Main Components of Epoxy Resin System Potting Compounds

I. Epoxy Resin

Epoxy resin, an epoxy oligomer, is a key component of epoxy potting compounds. It reacts with curing agents to form a three-dimensional crosslinked thermoset composite. In most cases, epoxy resin is used in liquid form and can be cured at room temperature or by heating.

During the curing reaction, liquid epoxy resin exhibits low shrinkage and excellent post-cure properties such as heat resistance and adhesion. It is one of the most widely used thermoset resins.

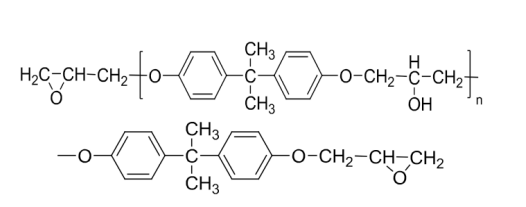

The structural formula of epoxy resin is as follows:

II. Curing Agents

Curing agents are essential for epoxy potting compounds. Different curing agents yield epoxy potting compounds with varying properties. The two most common types in epoxy formulations are:

- Acid Anhydride Curing Agents

- Used in two-component heat-cured epoxy potting materials.

- Common examples include liquid methylhexahydrophthalic anhydride (MeHHPA) and liquid methyltetrahydrophthalic anhydride (MeTHPA).

- Features: Low viscosity, high loading capacity, dual roles as curing agent and diluent. They release heat gently during curing and impart excellent 综合性能 to the cured product.

- Amine Curing Agents

- Used in room-temperature-cured potting compounds.

- While they can cure epoxy resin at ambient temperatures, their strong 刺激性气味,limited pot life, and exothermic reaction have led to reduced usage.

III. Thermal Conductive Fillers

Thermal conductive fillers in potting compounds are typically inorganic powders. Adding fillers significantly enhances thermal conductivity. Compared to the epoxy matrix, fillers offer higher thermal conductivity, better insulation, lower water absorption, and reduced coefficient of thermal expansion. Thus, adequate filler loading can notably improve processing performance and the 综合性能 of the cured product. In short, the performance of thermal conductive fillers is the critical factor in meeting potting process and product requirements.

IV. Other Additives

To meet specific performance needs, additional components may be incorporated:

- Diluents: Reduce viscosity for easier processing.

- Defoamers/antisettling agents: Improve processing characteristics.

- Flame retardants: Enhance safety and reliability.

- Coupling agents: Boost adhesion properties.

- Colorants: Meet aesthetic requirements.